Understanding the Milling Process

Elite Turning & Machining has about 20 different CNC machines designed to handle a wide range of machining tasks, including precise milling for perfectly crafted components and parts. We strive to meet all our customer’s needs for prototyping and production projects of all sizes, from short run projects to high volume production to meet your business’s demands. Whatever type of milled parts your company needs, Elite Turning & Machining can deliver on time with expert attention to detail and stellar customer service through every phase of your project.

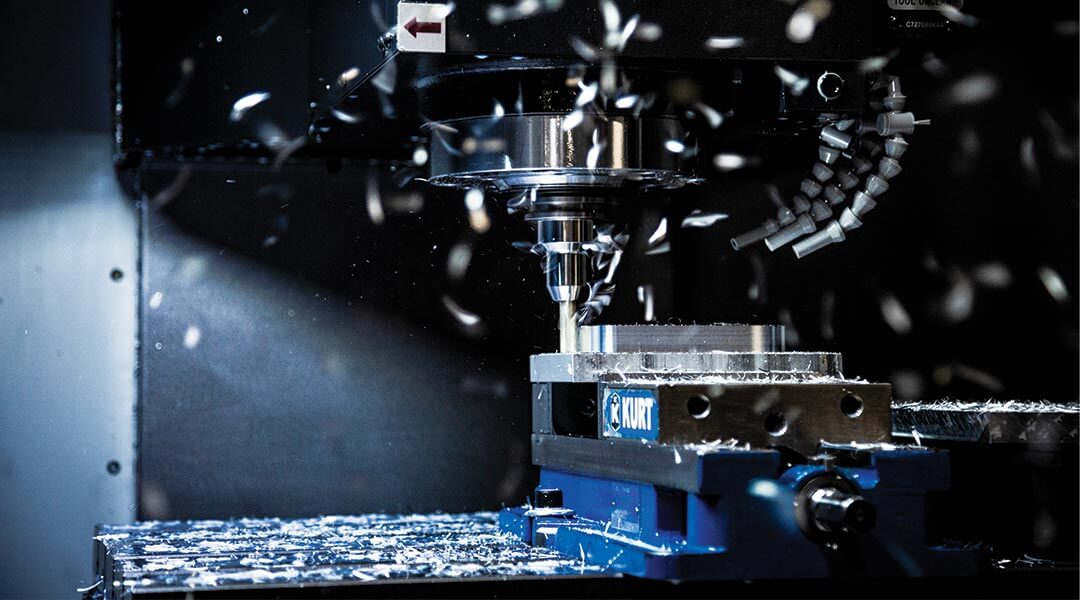

CNC milling is a relatively straightforward procedure, but it requires close attention to detail and a keen eye for quality assurance. At Elite Turning & Machining, our expertly trained and highly experienced millers will use a variety of milling tools to complete your order as required. We have a highly versatile array of milling equipment to cut down on setup and cycle times, which ultimately translate to lower manufacturing costs for our customers.

What Is Milling?

Milling is a type of subtractive manufacturing; the milling tool removes material from a workpiece or bar of raw material until it takes the desired shape. We fit a workpiece into the milling machine to brace it in place, and then a cutting tool is applied carefully to the parts of the workpiece requiring removal. When applied, the milling tool removes material from the surface of the workpiece until the workpiece takes the appropriate shape. This process is ideal for all types of odd-shaped parts and components, such as:

- Medical equipment.

- Optical device components.

- Tool components.

- Robotics parts and equipment.

- Automotive parts.

- Pump and valve housings.

- Testing fixtures.

- Aerospace tools and parts.

- Precision instruments.

- Consumer products.

- Power tool components.

Cut Down on Production Time with Milling from Elite Turning & Machining

Some of our milling machines use advancing cutting tools that operate in various directions across several axes. We can also adjust cutter speed, pressure, and rotation as needed to ensure every part is milled exactly to customer specification.

The CNC software in our milling machines ensures we can meet very low tolerance thresholds. Automatic tool changers, tool carousels, tool magazine, and various other fixtures enhance our milling processes and allow us to meet all deadlines with complete accuracy and the highest possible milling quality.

Elite Turning & Machining has the experience and tools necessary to fulfill orders of all sizes for all kinds of parts. Thanks to the versatility of our CNC milling machines and the cutting-edge software they use, we can cut down on your production times and provide high volume parts orders in less time than you likely expect.